A Guide to the Setup and Operation

of the Very Large Scale

Synthesizer |

Genomic Technologies Inc. |

|

|||||

|

|||||

|

|||||

Index

Page

VLSS Validate Software Tutorial

System Diagnostics and Priming

10

During a Run

12

Appendix A

Appendix B

The Validate

Software which controls the VLSS is a graphically

controlled user interface. The software allows the user the

ability to edit and store an almost infinite number of sequences.

The software is designed to be customized by the user as they

become more accustomed to the system which further increases the

efficiency of the user interface.

The next section

is an introduction to the Validate software. The intent is to

detail the features of the system and to suggest ways of future

customization for your laboratories needs.

The software is

initiated by double clicking on the VLSS icon with the Genomic

Technologies group. The startup screen will appear as the

system loads into memory. Clicking on the startup screen will

reveal the VLSS Main Screen.

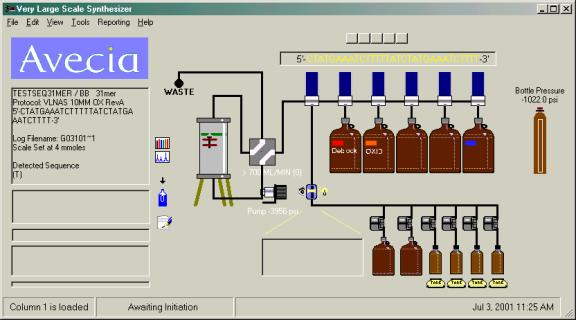

There are

several areas of the screen to take note of.

The set of

pull down menus at the top of the screen. These menus work

much the same as any pull down menus in a Windows application.

The menus give the user access to a variety of other screens that

can set default synthesis parameters, edit sequences, edit

synthesis protocols, and control valves within the VLSS. The

left hand side of the screen is reserved for status. The top

left status box shows what is going on for any loaded or running

column. The remaining boxes display a variety of status

information, which occur during a run. These areas are also used

for internal Debug information

The right

hand side of the screen shows a representation of the VLSS

fluidic schematic. Clicking on the valve or pump images will

toggle between activated and deactivated states for these

components. The system can be operated in safe mode, which

prevents the user from accidentally clicking on a valve image and

activating or deactivating valve.

The system can be equipped with reagent scales. The value of the weigh on these scales can be viewed if the user moves the cursor over a bottle image assigned to a scale. The amount of fluid in the container is displayed in milliliters, providing the correct density for the reagent has been entered into the scales section under the program setup.

The pressure in

the bottle blanket system is displayed on the far right of the

screen. The fluid system pressure is displayed under the pump

image and this display will turn red during a run when the

pressure exceeds 30 PSI. This is not a fault condition, only a

warning. The system is capable of operating with specification as

long as the fluid pressure remains below 60PSI.

Setting Up

the Program

There are a

variety of parameters, which are user configurable through the

Program Setup. Access this tabbed dialog box by selecting FILE

from the main menu and slide down to Program Setup.

The initial

setup should involve typing in the Organization and user names.

Once the Organization or Company name is entered it is a good

idea to save the program setup and exit out of the Validate

software. This will allow the software to register the Company

name and then when you restart the software any optional features

which are specific to your software license can be installed.

Among the

several tabs in this program setup dialog, there are a variety of

program parameters which can be customized for your specific

needs. Most of these parameters are self explanatory. Hold the

pointer above any of the parameter settings to invoke a short

description of the feature. The default settings, in most cases,

will suit the average user. There is one setting which must

be changed in order to operate the synthesizer. This

setting is under the OPTIONS tab and is designated Run In

Simulation Mode. This parameter is set by default to

Simulation. It must be unchecked in order to operate any of the

valving or sensors of the system. It is set to simulation upon

installation to avoid a host of error messages which are

generated when the controlling computer is not connected to a

synthesizer. This also allows the user to install the software on

an office computer to practice with the software or edit

sequences or protocols from a remote computer.

The user invokes the sequence editor by

either double clicking on the sequence editor icon in the Genomic

Technologies group or by using the pull down menus on the

VLSS Main Menu. Select EDIT and pull down to SEQUENCE.

The user invokes the sequence editor by

either double clicking on the sequence editor icon in the Genomic

Technologies group or by using the pull down menus on the

VLSS Main Menu. Select EDIT and pull down to SEQUENCE.

The sequence

editor is very simple to use. There are boxes for the user to

type the sequence name, client name and the actual sequence. The

client name is useful if your laboratory does any billing.

The sequence

files can be read by any standard editor program and are easily

imported to a variety of spreadsheet programs. The Genomic

Technologies Sequence Editor requires the user to name the

sequence. This is not the file name so the name is not limited to

eight characters. This is the name that will appear on the main

screen when the synthesis is running. When all the data is

entered, the user must save the sequence. Select save and a save

dialog box will appear. The default sequence directory is the SEQ

directory in the program directory, although the user can store

the sequence in any directory within the computer or any drive

located on a network if your computer is networked. Type the name

of the sequence. A date form of sequence naming can be useful for

laboratories that process many sequences. Press CR or

select exit or cancel to go back to the Sequence Editor and

continue editing additional sequences. If the user tries to exit

the Editor without saving the sequence a caution window will

appear indicating that the sequence should be saved.

The user can

only work on one sequence at a time and can choose New for

a blank template.

The Sequence

Editor is equipped with a Proof Reader. This feature is

useful for long sequences. The Proof Reader will speak through

the PC speaker although this sound not very good. A sound card

will enhance this feature quite dramatically.

The Sequence

Editor supports the full set of Cut, Copy and Paste

commands that come with most Windows applications.

Save your

sequence and exit.

In addition

there is a QUICK Sequence Editor selection under

the EDIT menu. This editor dialog is contained within the

Validate softeware and may offer a simpler interface for some

users. It has most of the basic functionality of the Genomic

Sequence Editor and does not require the user to jump out of the

main Validate software.

The Validate

Software can estimate the software consumption based on previous

synthesis’ consumption’s. The resources database file

is located in the database directory (Resources.mdb). This file

stores the reagent consumption per cycle for all reagents used

for each protocol. If new protocols are created or the edited and

a new name created for the protocol, this resource database needs

to be updated with the new reagent consumption information.

To prepare a

reagent consumption estimate, the user must first load a sequence.

Double click the column image to invoke a

sequence load dialog box. Use the common Windows file dialog box

to locate the directory where the desired file is located. Select

the sequence from the directory listing by double clicking on it

or highlight it with a single click and press enter or click OK.

Next choose the protocol desired and finally the 5’ DMT

condition. These file directory locations will be remember the

next time you load a sequence and protocol for more efficient

loading.

Double click the column image to invoke a

sequence load dialog box. Use the common Windows file dialog box

to locate the directory where the desired file is located. Select

the sequence from the directory listing by double clicking on it

or highlight it with a single click and press enter or click OK.

Next choose the protocol desired and finally the 5’ DMT

condition. These file directory locations will be remember the

next time you load a sequence and protocol for more efficient

loading.

Another way to

load a sequence to a column position is by using the drag-and-drop

method. Open a Windows Explorer window. Use the Explorer window

to locate the directory with the sequence file then click on the

sequence you want and while holding down on the left mouse button

drag the sequence file over to the column location. Let go

of the mouse button. The protocol selection window should open

followed by the DMT condition box. Make these selections to

complete the sequence load.

Access the

resources screen by clicking on Resources under the TOOLS menu.

Now that a sequence is loaded, the estimated reagent consumptions

for the run can be calculated and displayed on this page. You can

print this page and use the information to prepare the reagents

and load the reagent reservoirs.

Prepare the

column reactor according to the appropriate SOP and install it

onto the synthesizer by connecting the column inlet and column

outlet fluid lines. It is advised that an inert fluid filter

be used before the column to avoid high pressure problems during

the synthesis.

The fluid

system is now ready to be tested for external leaks. Access the Column

Packing screen under the TOOLS menu. Use this screen to

initially make the system flow at 100ml/min with Acetonitrile.

Check the system for fluid leaks around the column. If there are

no leaks, or any initial leaks are corrected by tightening the

tube fittings or replacing leaky fittings, Use the buttons on

the left of the screen to ramp up the flow rate to the highest

flow rate used during the synthesis. Recheck for fluid leaks and

correct any if found. Stop the flow and close the Column Packing

window when this step is completed.

Access the Manual

Function screen under the TOOLS menu. This screen provides

access to several programmable macro functions. These macro

functions instruct the synthesis to perform a series of

mechanical operations to deliver fluid to or bypassing the column.

Disconnect the

column and pre-filter from the synthesizer and place the column

inlet tube into a waste container. Most priming macro functions

are, or can be made to bypass the column however it is safest to

disconnect the column just in case.

Select the

Prime Ancillary macro. This macro will pump a small amount of

each of the reagents to waste. Watch each reagent bottle to see

if the fluid does indeed move up the dip tube when the proper

bottle/reagent is being accessed as a visual confirmation. This

procedure can be repeated if the user desires a longer prime to

account for clearance of longer fluid lines.

Select the

Prime Monomers macro. This macro will pump a small amount of

each of the monomers to waste. Watch each monomer bottle to see

if the fluid does indeed move up the dip tube when the proper

bottle/monomer is being accessed as a visual confirmation. This

procedure can be repeated if the user desires a longer prime to

account for clearance of longer fluid lines.

These tests can be performed before or in

place of priming.

The system is

equipped with several programmable diagnostic procedures. These

procedure instruct the synthesizer to perform several mechanical

operations and access the scale readouts to monitor the

performance of the unit to determine if the system is operating

properly. The functions are located in the TOOLS menu under Internal

Diagnostics.

There are three

diagnostics which are suggested to be performed before every

synthesis.

Disconnect the

column from the system and connect a calibrated restriction line

which creates appropriate back-pressure for the column size being

used. Place the outlet of the line into a 5L waste container make

of polypropylene. Place the waste container onto the monomer A

Scale. It will be necessary to move the monomer scale from its

position on the monomer shelve to the floor. There is extra

length of wire to accommodate this rearrangement. Select the Pump

Flow Rate Test. This test will pump acetonitrile through the

system at varying flow rates and the scale will be accessed to

determine if the correct amount has been delivered. The results

will be displayed on the screen as the test proceeds and can be

printed when the test completes.

Reagent Flow

Rate test

Monomer Flow Rate test

Perform the

Reagent Flow Rate test and Monomer Flow Rate test in the same

manner. Alternatively the Monomer FR TST-Low Consumption can be

selected when it is desired to minimize monomer usage.

Remember to

reconnect the column once the diagnostics are completed.

The run is

initiated by clicking the start button (Arrow button) under the

column. The run may take several seconds to begin while each

reagent scale is accessed and the amount is recorded.

During a Run

The system will record the decrease in

weight of each reagent vessel for each cycle. These measurements

can be accessed under Reagent Consumption in the Reports

menu. It is advised to manually record the weights as the

synthesis proceeds and to also record the reagent consumption of

reagents such as Acetonitrile, which do not have scales. For

those reagent which have scales, the weights are read by moving

the mouse cursor over the particular bottle of interest.

During a run the cycle status is displayed

on the bottom status bar. The position in the sequence is also

noted at the top of the main screen. Yellow bases are those that

have been completed. Blue Flashing bases is the current base

position. The remaining bases are black.

It may be

necessary to top off a reagent when the reagent container is

insufficient to contain the required amount for the total

synthesis. The most appropriate time to top off is during the

first few moments of the cycle. At this point in the process the

previous cycle’s reagent consumptions have been accessed by

the scales and no consumption (Or very little) of the current

cycle has occurred.

If the system is

equipped with reagent scales for monitoring the reagent

consumption during the run additional steps should be performed

to re-tare the scales.

Access the Scale Management screen by selecting it from the tools menu. The current values measured by the scales for each reagent can be viewed by moving the mouse over each reagent container image. To tare a container, double click on the tare button below the image of the container. This procedure will record the current value being measured by the scale and use this value as a starting point for the current cycles reagent consumption calculation.

If this process is performed during the cycle and after a particular reagent was consumed then the reagent consumption calculation would yield a zero value for the cycles consumption of that reagent. Subsequent cycles would accurately be calculated because all the tare values are reassessed during the beginning of each cycle automatically. Alternatively, if this process of re-tarring is not performed then the current cycles consumption would result in a very large number for the reagent consumption. Subsequent cycles would accurately be calculated because all the tare values are reassessed during the beginning of each cycle automatically.

In addition, the

user should make a note of the reagent top-off in the synthesis

notation record.

The synthesis notation record is accessed

via the sketch page icon next to the column image. Right-click on

this image to add a note during the run. The note will be time-stamped

automatically. Alternatively the image can be left-clicked to

view all the notes recorded.

All the notes are saved to the database

under the run record.

Upon completion of the run, the column image will be changed and a double bar will now appear across the column.

Post synthesis

procedures, such as a T-butyl amine wash, can now be performed.

It is advised

that the monomer vessels be emptied and filled with dry

acetonitrile and a monomer prime procedure be performed to clean

the fluid lines. Disconnect the column during these prime

procedures.

Perform a Pump

Flow Rate Test as done in the pre synthesis procedure, to confirm

proper operation.

Print out a

synthesis report and trityl report(if installed) for

documentation and include these with the run documents.

Work up the

column reactor as prescribed by the appropriate SOP.

Reporting

The Validate

software contains a variety of reporting functions. Your software

license may include additional reporting functions. The basic

functions are described below.

Under the Reporting menu selection you will find

Print Report for Loaded Column

Print Report for Archived Run

These reports

print out a synthesis report. The synthesis report contains

information about the sequence including sequence statistics such

as molecular weight and melting temperature. If a synthesis is

completed, the completion time is reported in the top section and

the run results such as reagent consumptions are printed at the

bottom.

If you synthesizer is equipped with a trityl monitor and trityl data was collected for a completed run then this menu selection can prepare a Trityl Report based on the stored data file. The data file is named based on a automatically named Run Index Number. The data file will have the “dat” extension and is contained with the “Data” subdirectory of the Validate program directory. The dialog should direct you to this data directory. Select the “DAT” file with the appropriate Run Index prefix.

As

mentioned the prefix is auto-generated during the start of the

run submission. It is based on a date code and is unique for each

synthesis. The prefix is shared by all files associated with the

run such as the log file “jbi” and job file “job”

as well as the notation file “txt”.

There is also a

Reagent Consumption selection under the Reports menu. This

selection displays a form with any accumulation consumption data

for the loaded sequence. There is a print button available on

this form and selecting this will print out a report containing

the consumption values for the loaded synthesis. To obtain

consumption values for a completed run, which is not still loaded

on the screen, select Print Report for Archived Run, which is

above this selection. The consumption data will be printed at the

bottom of the general synthesis report.

If your system

is equipped with a UV scanner, this selection will print out a UV

report.

The UV scanner

option allows the system to measure and save a chromatogram of

the effluent from a valve train. Scanning is enabled via the

protocol and many scans can be made during a cycle. The scans are

primary used to identify what monomer bases are being delivered

through the valve train.

This report

consists of a representative chromatogram collected during each

cycle in the synthesis as well as the standard chromatogram set.

There are

several miscellaneous reports that you will find throughout the

Validate software. Primarily these reports provide a hard copy of

what is being displayed on the screen.

Macro Function

Resource Calculation

Debug Diagnostics

Logfile Viewer

The Logfile

viewer function is located under VIEW in the main menu. This

function allows the user to view a log file for any given run.

When selecting this function, the user is directed to choose an

individual logfile with the extension “jbi” and a

prefix which corresponds to a run index number described above.

Initially the

Logfile Viewer will display the full contents of the logfile.

Every functioned that is called during the run is recorded so

there are often a lot of entries in the logfile. It is usually

difficult to locate any specific entry. The Logfile Viewer

simplifies this process by allowing the user to select a certain

subset of logfile entries. A drop down box is provided with a

listing of common subsets the user might want displayed. Once a

subset is selected press the Select View button and the subset of

the logfile is displayed. The user is not limited to this common

listing. The user may type in any search string to create custom

subset listing. The Viewer will scan the entire logfile and

display only the lines containing the search string. For instance

if “Valve” is typed into the dropdown box then all

valve functions will be displayed. If there are more entries than

the display can show a slide arrow is available to page down the

list. To initiate a new subset select View All to display the

entire contents of the logfile. If you do not do this a subset of

a subset will be displayed.

A print button

is available for printing the subset.`

Appendix A

The protocol is divided into Cycles. The beginning of each cycle is designated by a two letter code “CD” followed on the same line by a single character designator (i.e. “A” or “C”) separated by at least one space. These single letter designators must be unique in the protocol. The end of each cycle is designated by the “CD” function of the subsequent cycle. Any Single letter designator including lower case letters can be used as cycle descriptors with the following exceptions (+,-,*,!)

+ (Plus Sign) This cycle designator is used by the system and is imbedded into the job script when the user chooses to have the process retain the final 5’ trityl protecting group.

- (Minus sign) This cycle designator is used by the system and is imbedded into the job script when the user chooses to have the process remove the final 5’ trityl protecting group.

* (asterisk) This cycle designator is used by the system and is embedded into the job script at the beginning of the process. It is used as a pre-synthesis cycle and is run only once during the process.

!

(Exclamation mark) This cycle designator is used by the system

and is executed by the system whenever an exception condition is

identified by an ongoing function. Primarily it would be

performed when a “WT” function, described later, is

being performed and certain performance levels are not achieved.

Usually this cycle is comprised of a reset all function “RS”

which turns off all circuits. Followed by several functions which

cleanse the reactor placing it in a safe condition. The cycle

terminates by executing a hold command for the particular column.

If this function is omitted in a protocol, the system will jump

to subsequent steps in the protocol when an exception condition

is encountered. A temporary message will be displayed and a

record of the event will be made to the synthesis log file

however the process will NOT go into a hold state.

The final line of the protocol is -

CD Blank Cycle needed to parse file DONT

ERASE THIS LINE!!!

Do not erase this line. It designates the end of the protocol.

Protocol Auto Scaling - Protocol Three

Letter Functions

A protocol can be made to autoscale. Autoscaling is a feature which automatically sets the scaling factors of the system. Scaling factors are normally set in the Program Setup. There are several predefined scales which can be chosen by the user.

If the system will be operating at a variety of scales the user may want to have the protocol set this scaling factor automatically to avoid a mistake.

The scaling factors effect the functions CV and MX. These functions are described in more detail below and include parameters which evaluate to column volume quantities. The scaling factor enables the system to calculate a volume in milliliters from the number of column volumes prescribed by the function in the protocol and the actual column volume set by the scaling factor.

To designate Autoscaling within the protocol, include a line, usually near the top of the protocol, as follows

PRO xx

Where PRO is a three-character function designator for auto scaling and where xx is a number (Integer value) designating the scale. The allowed numbers for predefined scales (in mmoles) are (1, 4, 5, 10, 20, 30, 40, 50).

The predefined scales assume a support

loading density of 25ml/mmole. This value is attained by assuming

a support molar loading of 90umole/gm and a support mass density

of 0.44gms/ml. If supports being used have significantly

different attributes from these values then predefined scales

should be avoided for selecting of scale values

To designate a non predefined scale, or actual scaling factor substitute the actual Column Volume in milliliters (integer values only) for the “xx” in the PRO line in the protocol. Usually this value will be above 100mls, and should always be above 50 to distinguish it from a predefined scale (i.e. PRO 100).

If however it is necessary that a scale

or column volume be defined within the predefined range (0-50),

this can be done as described above with the following exception.

In the event that a column volume is exactly equal to one of the

predefined scale numbers then you cannot use this value to define

an actual scaling factor. Instead use a value slightly higher

integer value. For instance instead of entering 40 enter 41 as

the actual scaling factor so that the system interprets this to

mean that the column volume is 41mls and not that the auto scale

is 40mmole and thus the column volume is 1000mls. Usually column

volumes are much higher then these predefined scale values.

Protocol Two Letter Functions

The following is a list of the protocol editor control codes and their descriptions. Each code begins with a unique 2-letter designation followed by several parameters separated by at least one space. The use of any other characters for delimiters, such as tabs should be avoided. The number of parameters is dependant on the particular code.

CD Cycle Designator Format {CD x} Where x is a single letter designation for the cycle

SC Sub Cycle Description Format {SC name} Where name is a description of the subcycle that follows.

The case where name is “Deblock” is special. This indicates the beginning of a cycle or cycle barrier. There should only be one occurrence of “SC Deblock” within the cycle. A special set of “Begin Cycle” operations are carried out, for example the polling of scales to determine the previous cycles reagent consumption. In addition the Deblock subcycle is used as a marker to calculate the cycle position for displaying the Sequence on the main screen and the indication of the current cycle.

Other subcycle definitions including Deblock, Coupling and End_Cycle are used as breakpoint positions. Breakpoints can be set for future cycles in the process. The specific point in the cycle for the breakpoint or hold operation can be further specified as before the Deblock, before the Coupling step or Before the End_Cycle operations. The positions at which these subcycle declarations will determine where the process goes into a hold.

AU

Audible function Format {AU “filename”} Where filename

is a filename of a WAV file located in the program directory. The

function plays the wave file without any delay in the run

AP Audible Pause Format {AP “filename” “Message”} Where filename is a filename of a WAV file located in the program directory. The function plays the wave file and then pauses the run. If the Message field is included a window will be displayed with the message.

EJ

End Job Format{EJ} used to designate the End of a run. Place this

function at the end of the post synthesis cycles usually

designated {+} or {-}.

WA

A Wait Step Format {WA xxxx} Where xxxx is the number of

milliseconds to suspend processing of the job script.

RS

RESET ALL. This function causes all circuits controlled by the

system to be deenergized. This function is used during a HALT

condition as well as during an exception controlled shutdown

process designated by the “!” Cycle

WT Wait Trityl Function. This function is used in conjunction with the inline UV spectrophotometer option. The function can be used in three modes, Set Wavelength mode, Integral mode and Threshold mode. If the third parameter is a comment or nonnumeric then the Set Wavelength mode is assumed. The absorbance at the wavelength designated by the second parameter is recorded by the system and stored in the History file.

If

the third parameter is numeric then the function operates as

essentially a wait step. The system will continue to function in

its current state until the parameters of the function are

achieved and the process can move to the next step in the

protocol. Typically this function is used during the Deblock step

to determine if enough trityl color as been eluted from the

reactor and that detritylation is complete. The Integral method

will wait for an accumulation of color whereas the Threshold

method is waiting for a maximum level to be reached and then a

subsequence minimum level. Which of these two method types is

distinguished by the sixth parameter. If this parameter is

a numeric type then it is assumed that the Threshold method is to

be used. Otherwise the Integral method would be assumed and this

sixth parameter would actually be a comment field for display on

the main screen during operation of the function.

The

following table lists the different usages of the parameters for

the methods described.

FF

FD

AB

AE

VF

Valve Function Format { VF xxxx Y

My_Message} Where xxxx is the valve map of the valve to be

controlled, and where y is the state (1 for on 0 for off) of the

valve and My_Message is a message that is displayed during the

operation of this function. Separate multiple words in the

message with underscores so that the line is parsed correctly.

This function takes virtually no time to perform so make note

that the message will be barely visible.

CV

Column Volume Function { CF xxxx My_Message} This is

essentially a wait step where by the wait time is determined by

the current flow rate set previously using the PF function and

xxxx is the number of column volumes in mls, delivered to the

column. My_Message is a message that is displayed during the

operation of this function. Separate multiple words in the

message with underscores so that the line is parsed correctly.

This function should be used exclusively for protocols that are

intended to be scalable.

MX

A Mix function Format {MX xxx yyy m a

b My_Message} This function delivers two reagents by

performing an inline mix actuating the valves designated by xxx

and yyy alternately. The “m” parameter represents the

number of discreet mixes. The “a” parameter represents

the column volumes of the reagent controlled by the xxx valve and

the “b” parameter represents the column volumes of the

reagent controlled by the yyy valve. The “a” and “b”

parameters are in mls. The function assumes a flow rate set by a

previous PF function. My_Message is a message that is displayed

during the operation of this function. Separate multiple words in

the message with underscores so that the line is parsed correctly.

This function should be used exclusively for protocols that are

intended to be scalable

MW

A Mix function the same as the MX function except with

parameters a and b the actual wait times are explicit and not

derived from Column volume amounts. Parameters a and b are in

thousandths of a second so an amount like 2000 would represent 2

seconds.

A up to date

listing of parts can be obtained from Genomic@Genomictechnologies.com